The Braillo Difference

Braillo Braille Printers - See (and Feel) The Difference

Producing Braille at high speeds while maintaining quality is a demanding mechanical process which requires a heavy-duty, precision-made Braille printer in order to meet these rigorous demands. As opposed to personal use Braille printers, a production Braille printer is designed and built for continuous operation – as in 15+ hours of use at a time, with the user only stopping to reload paper no more than once per hour (when using rolls, the user may only have to stop once per day). Personal Braille printers, or those made to look like production printers, are built to produce low quantities of Braille documents. They can be great machines for low volume Braille printing, however, due to their construction and paper handling methods, they are poorly suited to produce large volumes of Braille documents for businesses, schools or government entities.

Production Braille printing is on a magnitude more demanding than consumer Braille printing.

To demonstrate the differences between Braillo production Braille printers and those of its competitors, compare the mechanical parts. When critical parts such as these fail, Braille production stops. Looking at the images below, which Braille printer would you trust to meet your Braille production requirements? Click on any image to enlarge it to see the obvious: Braillo is in a class of its own when it comes to production Braille printing.

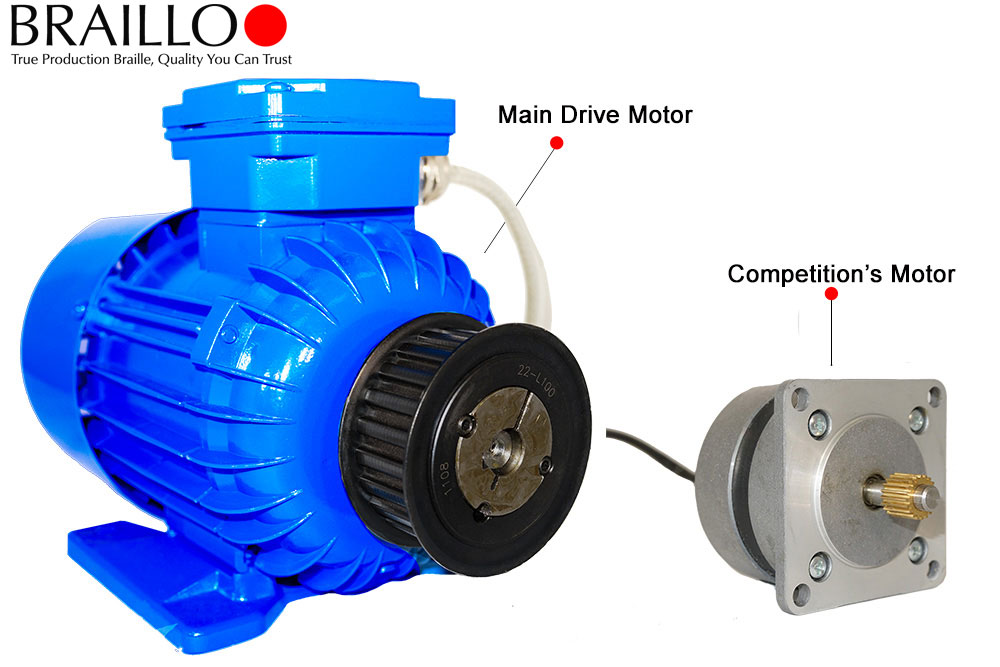

Braillo Main Motor Vs. Competition

Production Braille printers need industrial level motors to meet the heavy demands of Braille production. Braillo uses a powerful, main motor to operate the printing mechanisms, and then a separate, smaller motor to run the paper handling component. In contrast, the competition uses a single, small, lightweight motor to run all of its operations.

Also interesting to note is the size of the drive wheel on each main motor shaft.

Braillo Timing Wheel Vs. Competition

The timing wheel is part of what controls the entire operation of a Braille printer – an essential component to ensure proper spacing and dot alignment.

Braillo timing wheels are made of case-hardened steel and are significantly larger in size compared to the tiny wheel made of lightweight aluminum used by the competition.

Braillo Drive/Timing Belt Vs. Competition

In partnership with the both the timing and drive wheels, the main drive/timing belt controls the printing operations. In a Braillo, this main belt wraps around two sets of timing wheels and the main motor drive wheel.

With high levels of torque necessary for high speed Braille production, the drive/timing belt must be strong and extremely durable for dependable operation. Braillo uses a thick, heavyweight belt made of thick flexible rubber which is highly durable. In comparison, the competition uses a lightweight rubber band.

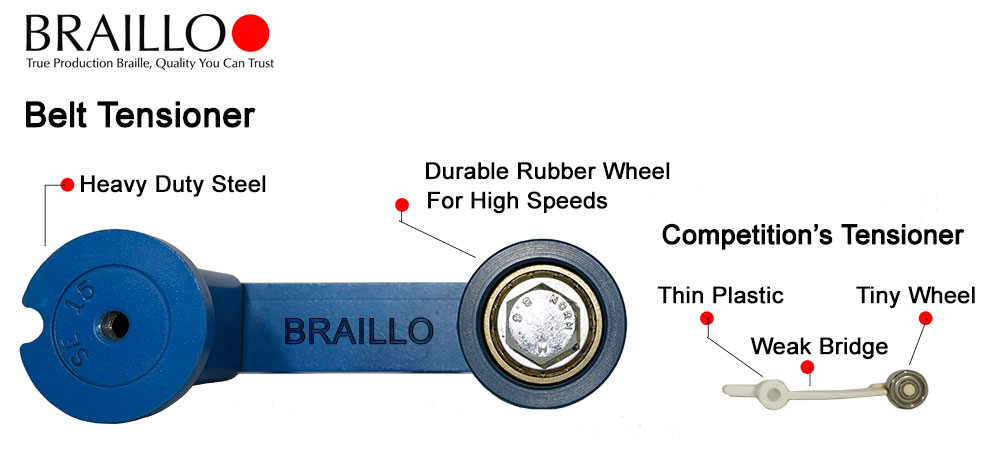

Braillo Belt Tensioner Vs. Competition

Keeping the drive belt taught ensures proper Braille line and dot spacing – a loose belt will result in errors in Braille production, incorrect Braille dot height and location, as well as potentially damage the Braille Printer.

Braillo uses a thick, heavy duty steel belt tensioner that provides constant and strong pressure, while the competitor uses a thin plastic tensioner susceptible to bending and breaking while under the lightest stress.

Braillo Cooling Fans Vs. Competition

Running a production printer for numerous hours each day, causes heat build-up – something which can potentially harm electrical components, or cause the user to have to stop production and let the printer cool down.

Braillo uses (2) heavyweight metal fans to remove hot air, while the competition uses only (1) lightweight plastic fan.

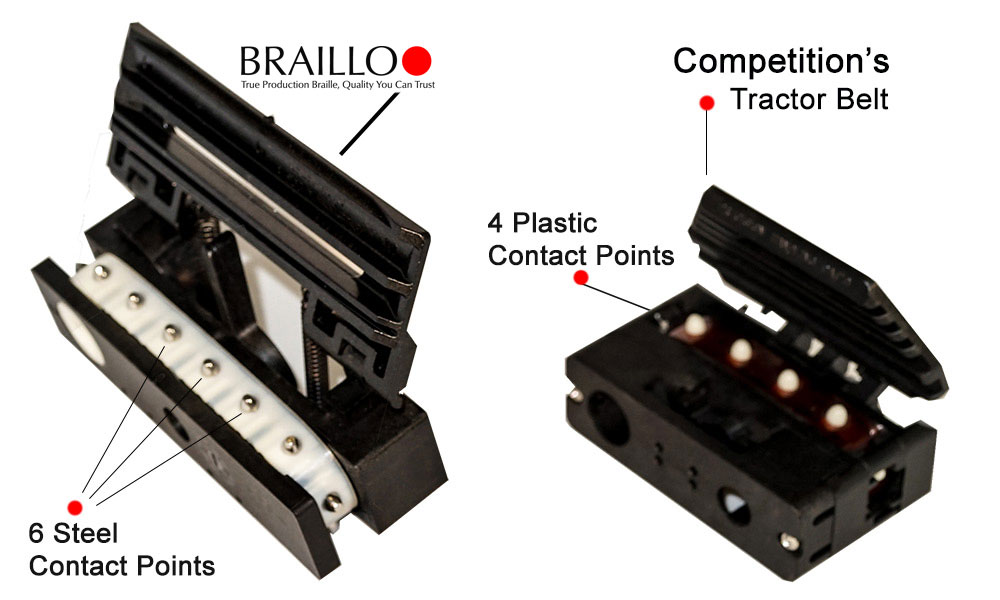

Braillo Tractor Belt Vs. Competition

Tractor belts feed the Braille paper through the printer. It is essential that the paper feed through the printer accurately.

Braillo uses heavy duty tractor feed units with 6 steel contact points and a durable belt mechanism, while the competition uses a thin plastic belt with just 4 small plastic contact points, making the paper susceptible to misalignment and tearing.

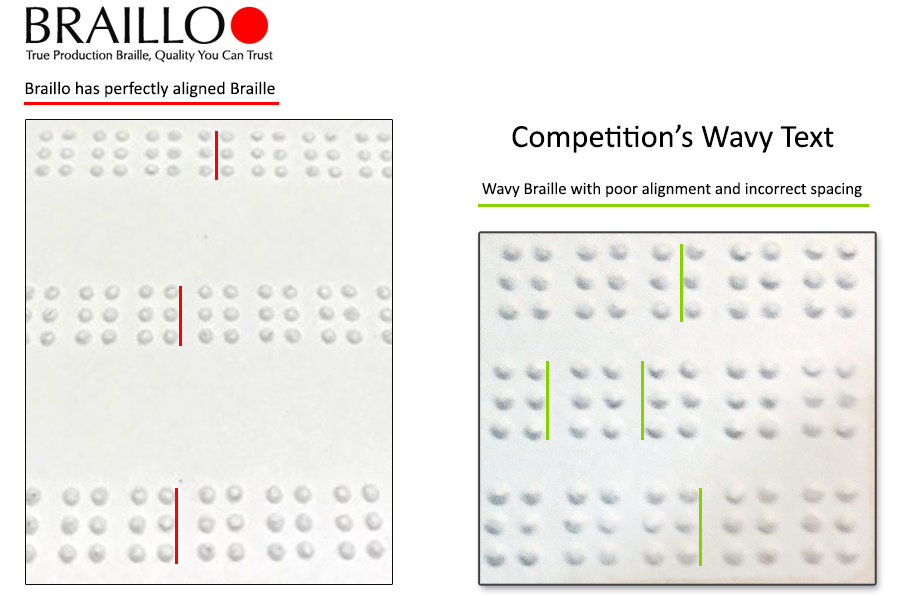

Perfectly Aligned Braillo Braille Vs. Competition

Braillo Braille is known as the easiest to read and the reason is simple, our Braille is perfectly aligned and the dots are where they’re supposed to be. When the Braille isn’t where it’s supposed to be, the reader has to try and guess what the word is supposed to be, or stop and re-read the sentence.

Look closely at the image and you’ll see that our competition’s Braille output is wavy and the dots within the rows and columns are not perfectly aligned, whereas the dots from a Braillo are exactly where they need to be.

Investing in A Braillo Braille Embosser

Braillo is the world’s leading and largest manufacturer of true production Braille printers. Braillo Braille printers are built to serve high volume Braille printing, starting with the Braillo 300 and all the way up to large-scale, high speed Braille Book/magazine production of the Braillo 650 SF, which folds, adds a cover and staples a book/magazine.

Braillo is often asked why it’s production Braille printers are heavier, larger and more expensive when compared to the lower-priced alternatives sold by its competitors. The answer is clear: Braillo builds true, heavy-duty, high quality, durable printers for large-scale Braille production. Braillo’s competitors build consumer-grade printers with consumer-grade parts, and sell them as production-level printers – there is just no comparison between the two.

When you purchase a Braillo printer, you are investing in a machine that will produce high quality Braille documents, books and magazines for decades. Countless Braillo printers from the 1980’s are still being used today – no other manufacturer can say that.